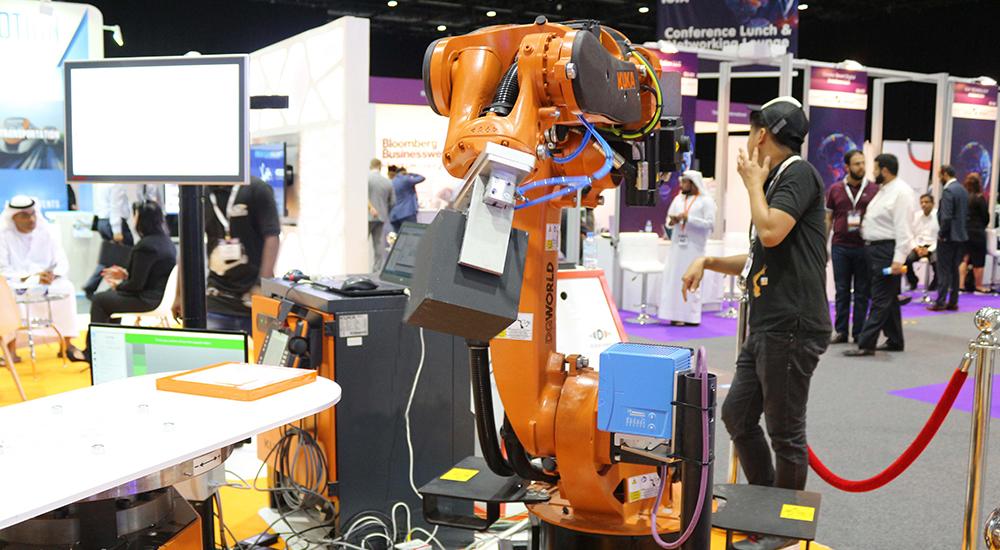

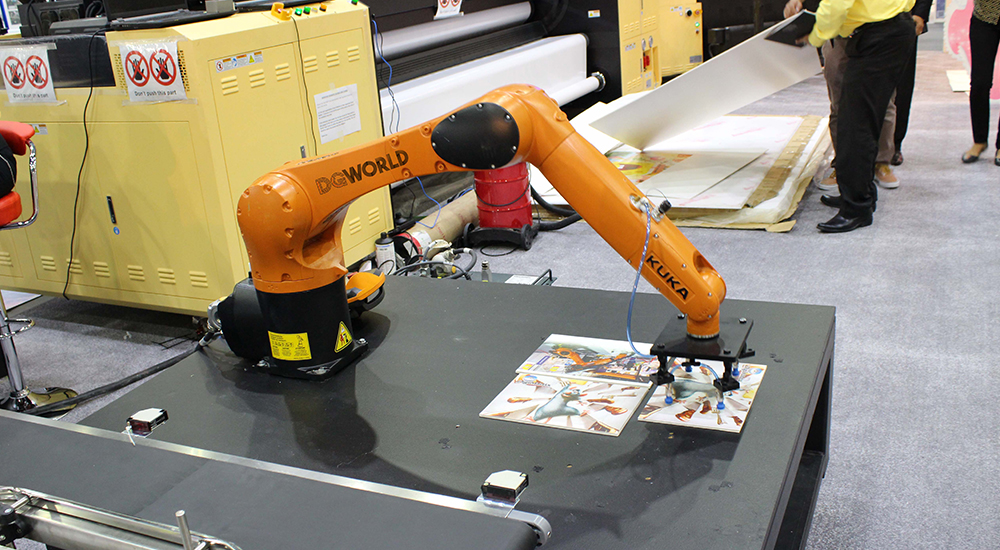

PalletBOT is a customizable robot palletizing system that performsthe task in the needed way, improving the safety standard and quality. The robot is designed for a high level of automated performance.We are proud to partner with KUKA on this solution.

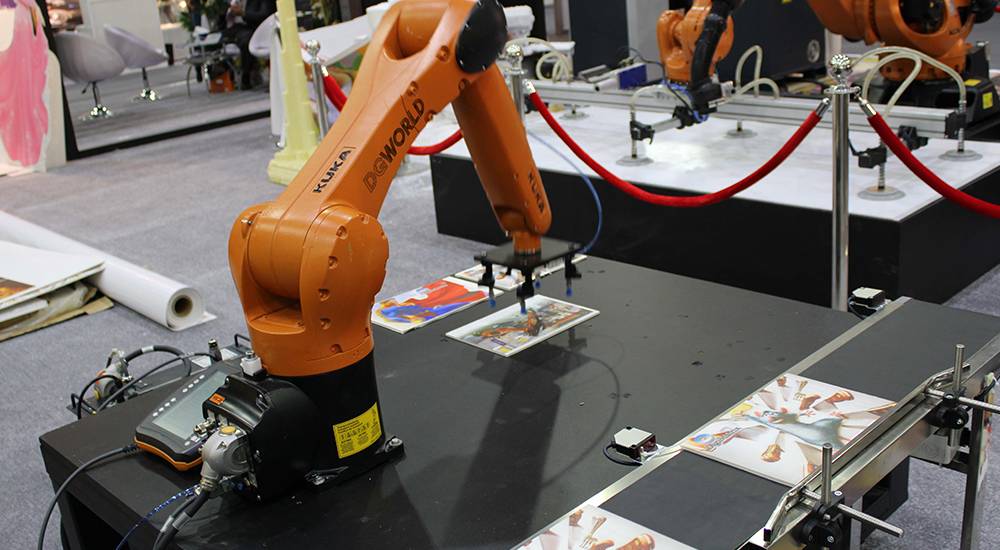

- Inline Palletizing

- Layer Depalletizing& Palletizing

- Mixed Case Palletizing

- Layer Palletizing in the Freezer

- Powerful

- Versatile

- Compact

- Minimal maintenance

Utmost precision and repeatability. With their streamlined, lightweight design, PalletBOT achieve greater dynamic performance, shorter cycle times and higher throughput.

PalletBOT comes with a wide range of different payload capacities, reaches and special variants, ensuring that you will always find the right solution, no matter how challenging the palletizing task.

The compact and streamlined design of PalletBOT enables quick and easy integration into existing systems. Their low disruptive contours extend the effectively usable workspace and allow innovative cell concepts.

All components of PalletBOT are equipped with low-wear drive trains. The advanced and robust design has extremely long maintenance intervals – with an availability of 99.995 percent and maximum energy efficiency.

Fork gripper: ensures reliable, gentle and precise stacking of all product types. It can handle up to 600 units per hour.

Double fork gripper: stacks bagged goods and cardboard boxes with a capacity of up to 900 units per hour; this is also possible by moving two units per travel path.

Finger gripper: high capacity tool for stable bags. It can palletize up to 1,200 bags per hour.

Double finger gripper: used if large quantities of stable bags need to be palletized. It can position up to 1,900 bags per hour for the palletizing process.

Pallet gripping device: The installation of a pallet gripping device allows for feeding the empty pallets without an additional empty pallet conveyor.

Suction gripper: recommended for bundles with sanctionable surfaces: it can stack up to 400 bundles per hour while gently handling the product. Even unstable packaged goods can be palletized reliably.

Parallel gripper: performs especially well when palletizing stable bundles with parallel side walls, i.e. cardboard boxes: it can stack up to 600 cardboard boxes per hour.

Special gripper: For individual requirements, special gripping systems are developed and dimensioned for the specific products and performance characteristics.

For more information, please reach out to us on:

www.dgworld.com

info@dgworld.com,

+971 800DGW800

Plot 20107, JAFZA South, Dubai, UAE

P.O.BOX 32067 Dubai, UAE