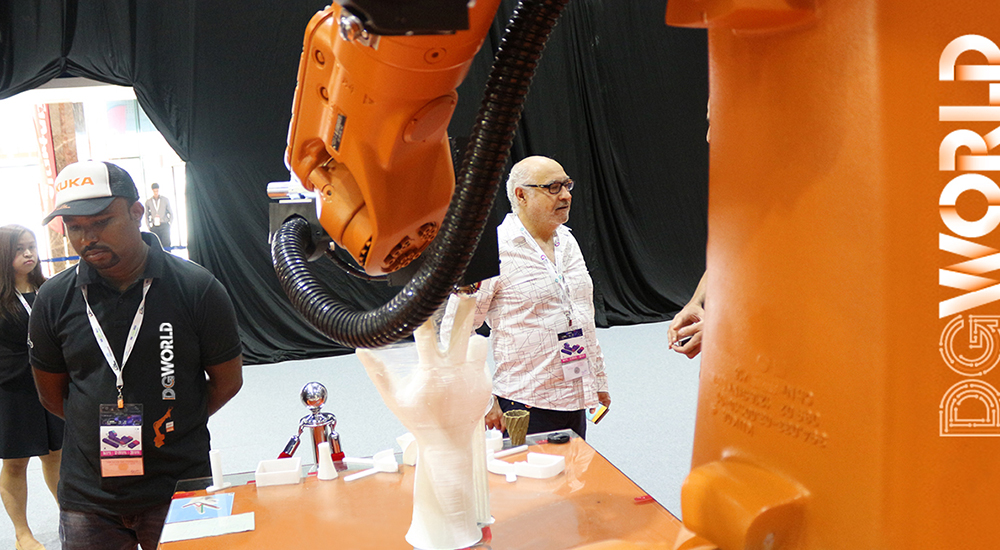

3D printing combined with industrial robots could be a novel yet promising approach to manufacturing. As manufacturing technologies evolve, this combination could be one of the solutions to the growing move towards greater digitization and smart manufacturing.

The combination of the industrial robots and 3D printing can be achieved in two ways.

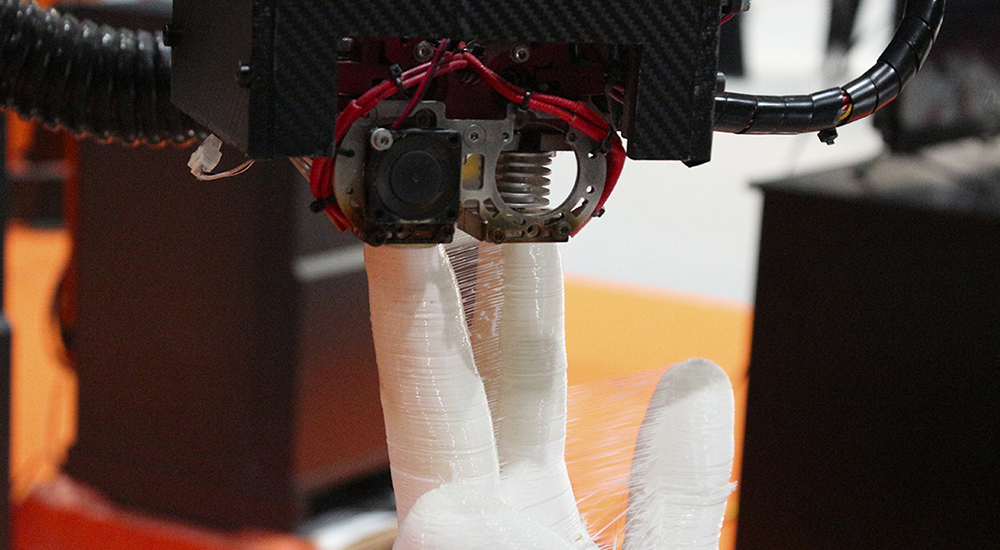

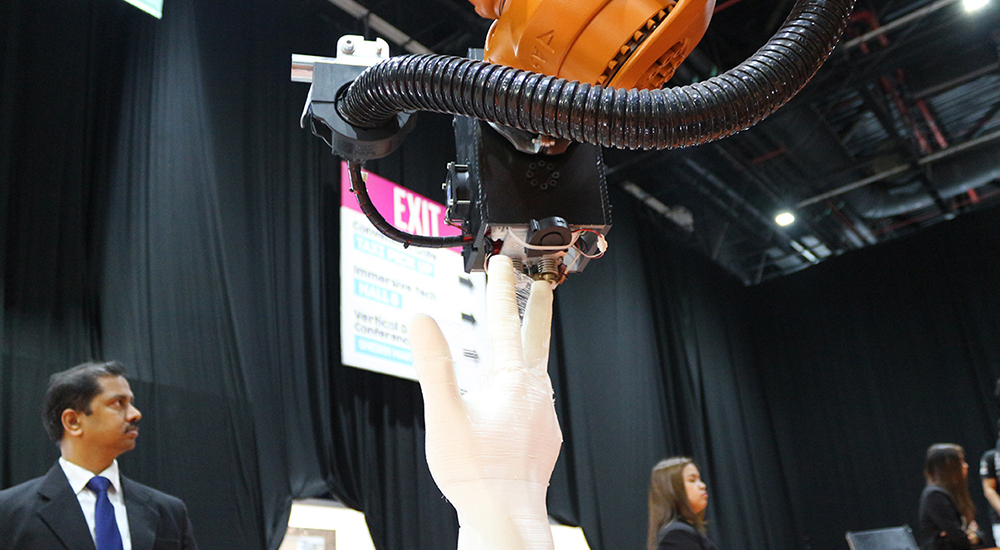

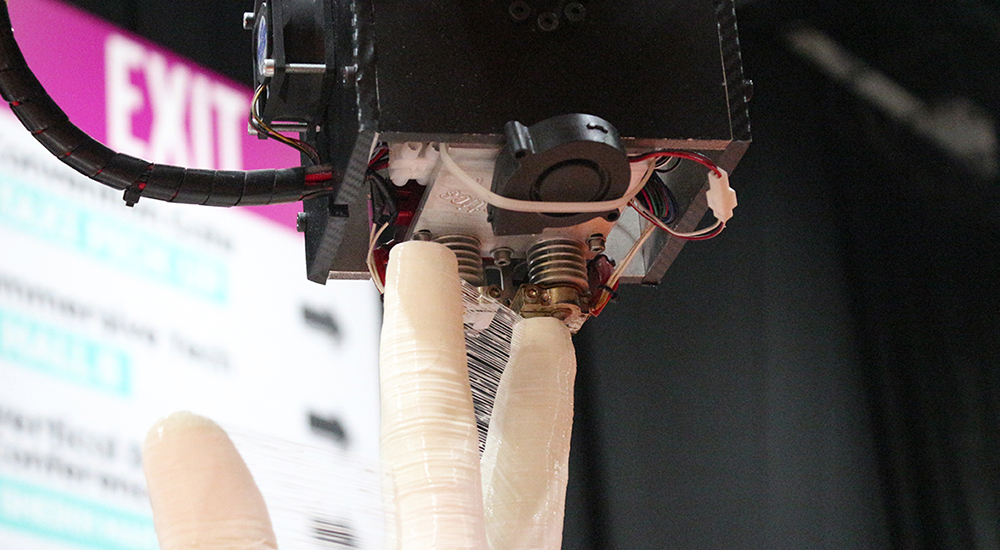

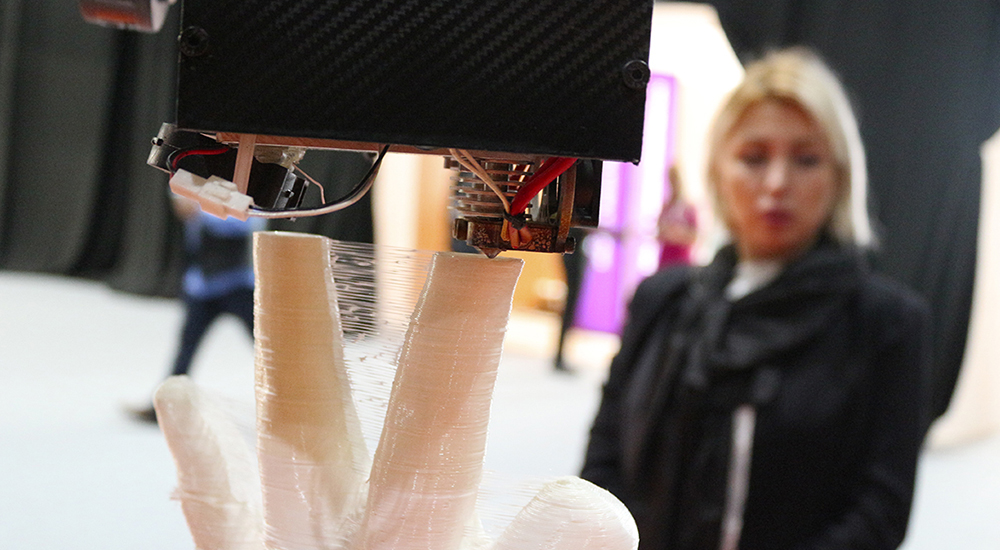

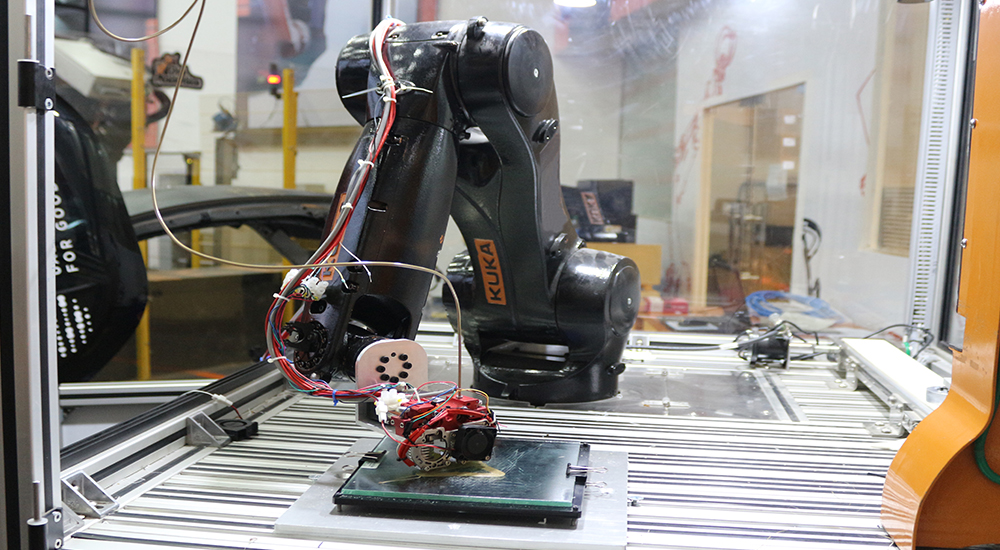

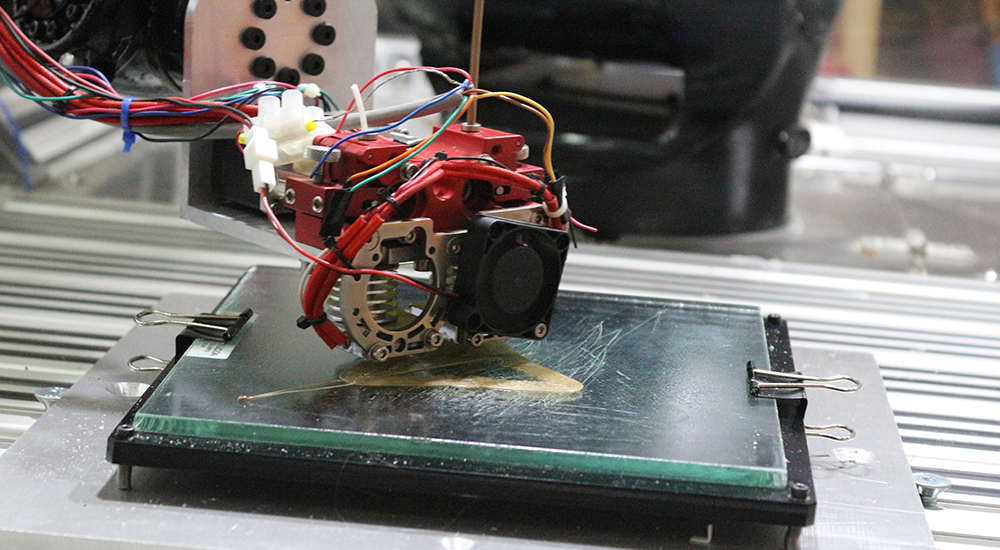

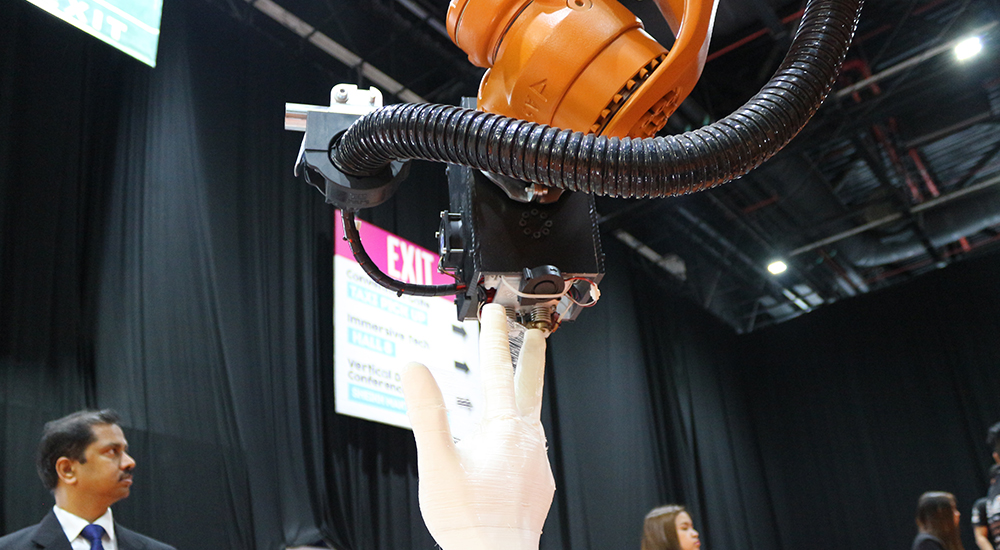

- The first way is to equip a robotic arm with a material deposition head.

- The second way to bring 3D printing and robotics together is by creating an integrated solution where industrial robots assist 3D printing at various production stages

Also, the Post-processing 3D printed parts can also be automated with the help of robotics.

The benefits of robotics in 3D printing:

- Larger parts

- Freeform manufacturing

- Reduced material waste

The construction industry is the one of the biggest beneficiaries of robotic 3D printing. Some construction firms have turned to the industrial robotic arms to 3D print with a range of materials.

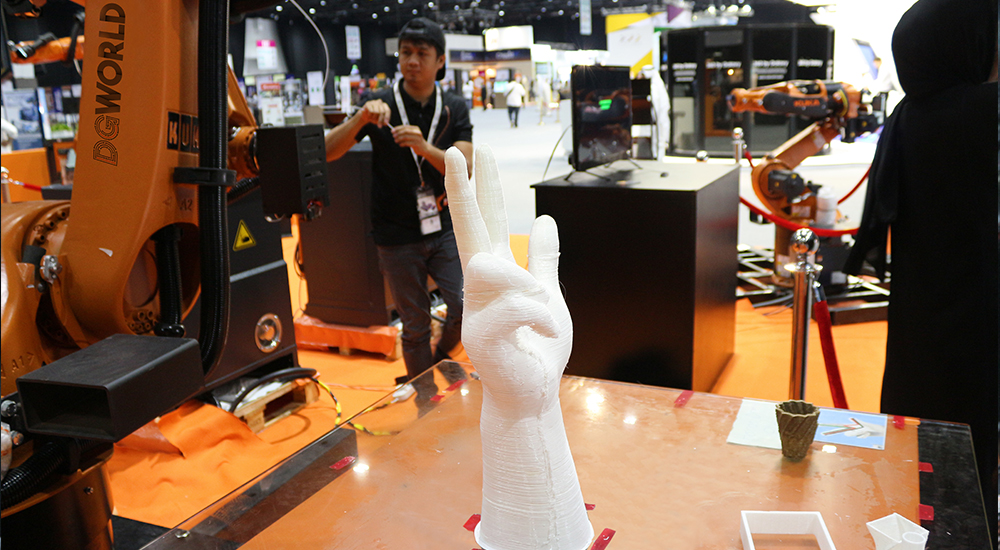

In DGWORLD, we achieved concrete extruder to create geometric structures by using the 3D printer whichenables the designer and architecture to experiment with different shapes thanks to the freedom of movement of the industrial robotic arm.

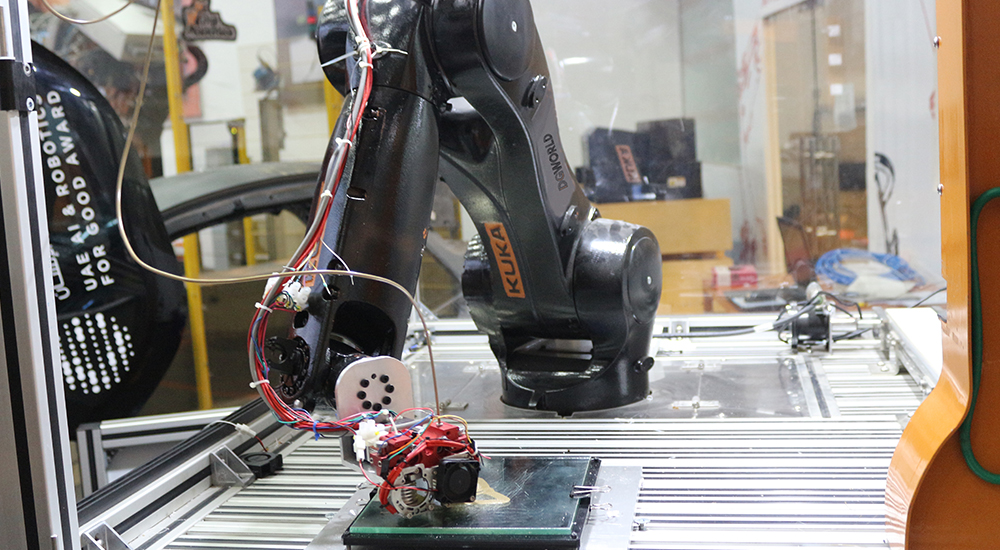

A 6-axis robotic arm, repurposed as an integrated 3D printing, milling and sculpting platform, enables shifting between fabrication modes and across scales using different end effectors. Promoting an integrated approach to robotic fabrication, novel combination processes are demonstrated including 3D printing and milling fabrication composites. In addition, novel robotic fabrication processes are developed and evaluated, such as multi-axis plastic 3D printing, direct recycling 3D printing, and embedded printing.

Outlooks

Intelligent industrial robots and additive machines combined with artificial intelligence could have a much broader range of applications, including smart and automated repair.